Valves are pipe notes for opening and closing pipes, operating inflow, adjusting and operating the main parameters of the transported substance (degree of question, working pressure and total flow). According to its effect, it can be divided into shut-off valves, check valves, regulating valves, etc. The valve spring can be said to be a key component of the valve. Among them, the round cylindrical spring is common, and it is naturally sometimes required according to the design plan. It is not the same to use square wire spring or wave spring.

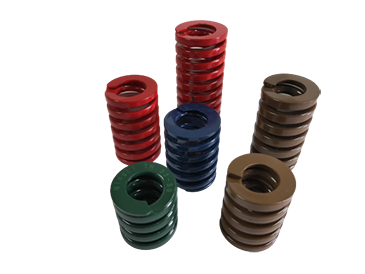

Valve spring design

There are often customers who give feedback like this: People now use springs to have unstable force values; force attenuation coefficients; and even breaks. So people's first response is usually to let customers come and see the random length changes before and after the spring is used. Yes, the spring is shortened. Why is it shortened? Because the spring is deformed, the spring is over-stressed during use. A slight over-earth stress will cause the spring to be deformed, and it will break if it is more serious.

Precision spring

Most design plan technical engineers match this kind of work. The first solution is to change the raw materials. The production of valve springs will not be as good as the current raw materials, and then try to change the harder raw materials, the compressive strength will be higher, and it will be more difficult. Deformed. If it is not good enough, it will consider whether the method of raw materials is not good and whether it is necessary to change imported raw materials? Or to import springs? The cost of the valve is increased as much as possible, and the competitiveness is reduced.

In the entire process of spring design, raw materials are an element that endangers the fatigue life of the spring, but it is not absolute. Secondly, the higher the compressive strength of the raw material, the better it will be fatigue under the working conditions of in-situ stress. However, when the raw materials with high compressive strength are selected under the condition of more severe in-situ stress, it is easier to break because of the accompanying resistance. The compression strength is increased and the strength will be higher; the winding ratio of the spring and the spiral angle are very harmful to the fatigue of the spring, so it can be said that all the design schemes and physical specifications of the spring endanger the fatigue and reliability of the spring. Sex.